In 20 years of manufacturing and over 28,000 heat pumps delivered, we have a very clear picture of what happens in the field. And that picture is unambiguous: heat pumps are exceptionally reliable technology. A quality unit will run trouble-free for 15 years or more, and we back our heat pumps with 5- to 10-year warranties because we trust that reliability.

Still, every now and then a customer calls to say their “heat pump isn’t working properly.” In the vast majority of cases, the problem turns out to have nothing to do with the heat pump at all.

Over 90% of problems don’t originate in the heat pump

This number comes straight from our service records. Out of every ten reported issues, on average only one involves an actual heat pump fault. The remaining nine have their cause elsewhere: in the heating system, in its settings, in neglected maintenance, or it’s actually completely normal behaviour that the customer simply isn’t familiar with.

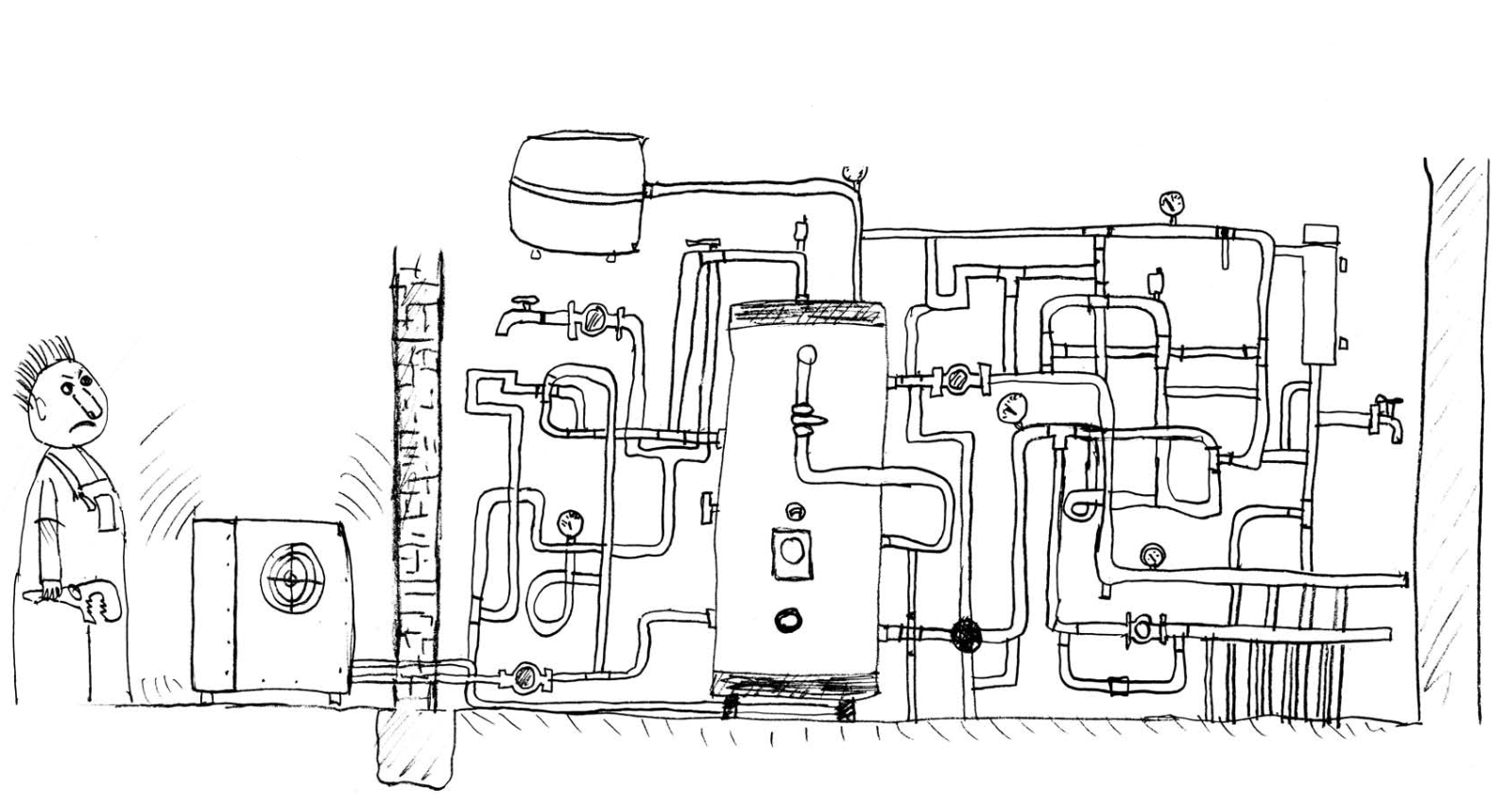

A heat pump is one part — an essential part, granted — of the entire heating system. For it to work correctly, it needs the cooperation of other components: the circulation pump, filters, expansion vessel, controls, piping, and heat emitters. When any of these elements isn’t working as it should, the effect shows up in the behaviour of the whole system, and the customer understandably calls the heat pump manufacturer.

A heat pump is not a gas boiler

A significant share of the queries we handle on our service line aren’t related to any fault at all. They’re a consequence of the fact that a heat pump works fundamentally differently from a gas boiler — the thing people were used to for years. This isn’t the customer’s fault — it’s a different technology with different behaviour, and it takes some getting used to.

”The radiators are cold, but the house is warm”

This is probably the legendary phone call that every heat pump installer receives, and among professionals it’s already a legendary story. The customer touches a radiator, finds it lukewarm, and immediately calls to complain. The technician asks: “What’s the room temperature?” The answer: “22 degrees, but the radiators are COLD — they’re not working!”

With a gas boiler, you can tell the heating is working simply by touching the radiator — it’s scorching hot, you can’t keep your hand on it. The boiler heats water to 70—80 °C, the radiator blazes away, and shortly after it shuts off. A heat pump works the opposite way. It delivers water at a lower temperature — say 35—45 °C — but continuously. The radiator feels pleasantly warm to the touch, not hot. The house, however, is heated to the desired temperature, steadily, without fluctuations. The system is working exactly as it should — it just looks different from what we’re used to.

A scorching radiator doesn’t mean better heating. It just means higher losses and a bigger bill.

”Why does the heat pump run all day?”

A gas boiler fires at full output, heats up quickly, and shuts off. A heat pump does the opposite. It runs for long stretches at low output, maintaining a stable temperature. Modern inverter compressors modulate their output continuously based on actual demand. Think of it as the difference between cruising on the motorway at a steady speed and constantly braking and accelerating in city traffic. Smooth, continuous operation is always more efficient. Frequent on-off cycling (short-cycling) is actually undesirable and signals a problem with the system settings.

”The water from the heat pump is only lukewarm”

A gas boiler routinely delivers water at 70—80 °C. A heat pump operates most efficiently at 30—50 °C, and that’s perfectly fine as long as the heating system is properly sized. Underfloor heating with a flow temperature of 35 °C will heat a house just as reliably — simply by different means. Higher flow temperatures are possible but come at the cost of significantly lower efficiency — every extra degree costs energy.

”Water is leaking from the outdoor unit and it’s making noise — or the outdoor unit is on fire”

With air-source heat pumps, a regular defrost cycle is a normal part of operation. At low outdoor temperatures, frost forms on the evaporator and the heat pump periodically removes it. The result is water pooling under the unit, water vapour rising from it, and a briefly different sound. It’s not a fault — it’s physics. As long as the unit has proper condensate drainage, there’s nothing to worry about.

”The electricity bill is higher than I expected”

A heat pump does consume electricity, but from every kWh of electricity it produces 3—5 kWh of heat. A direct comparison of a gas bill and an electricity bill makes no sense without converting both to actual delivered heat. If a customer used to spend 40,000 CZK a year on gas and now pays 25,000 CZK for electricity, they are saving — even if that electricity bill “seems like a lot.” The actual savings compared to a gas boiler depend on individual circumstances and, in today’s turbulent energy market, cannot be predicted in general terms without knowing the specific details.

”The heat pump shows low pressure, so I topped up the water”

This is one of the most common and potentially most dangerous mix-ups. Under certain operating conditions (such as a frozen evaporator or another issue in the refrigerant circuit), a heat pump may display a low-pressure warning. But this refers to the refrigerant pressure inside the heat pump, not the water pressure in the heating system.

A customer used to a gas boiler — where low pressure on the gauge means “top up the water” — does the same thing. But adding water won’t fix a refrigerant pressure problem and can even cause further complications in the heating system, such as overfilling the expansion vessel or diluting the corrosion inhibitor.

If the heat pump reports low pressure, the correct course of action is to contact service, not to reach for the filling valve.

What actually causes operating problems

When a problem does occur and it’s not just a misunderstanding, its cause is almost always in the heating system, not in the heat pump.

Clogged filters

Magnetic and mechanical filters in heating circuits capture impurities and protect the heat pump’s heat exchanger. When they clog up, the flow rate drops and the heat pump starts working inefficiently. Even worse is when filters are missing altogether — impurities then damage the heat exchanger directly, and the resulting repair is expensive.

Prevention: Inspect and clean filters at least once a year. A simple task that takes a few minutes and saves thousands.

Insufficient heating water flow

The heat pump needs adequate water flow to transfer heat properly. When flow drops due to undersized piping, incorrect circulation pump settings, or clogged filters, the system risks overheating or even freezing of water in the condenser.

Prevention: A proper hydraulic design of the heating system and regular checks of pressure conditions.

”But you designed that circulation pump”

We hear this a lot. When it turns out that the circulation pump doesn’t have enough capacity for a given heating system, the customer’s logical reaction is: “But you supplied it, so it must be fine.”

The reality is more nuanced. As a manufacturer, we supply a standard circulation pump with the heat pump that covers the majority of typical installations. Whether it’s sufficient for a particular house depends on factors we cannot know in advance: the length and diameter of the piping, the number and type of heat emitters, the height differences in the system, and the number of bends and fittings. All of these affect pressure loss and therefore the requirements for the circulation pump.

Correct sizing of the circulation pump is part of the hydraulic design of the heating system, which is prepared by a designer or installation company based on the specific conditions in the building. We supply the machine, but how it performs in a specific house is determined by the quality of the design and installation.

Pressure drop in the system

Low pressure means low flow and therefore operational problems. Common causes include a water leak in the heating system, a faulty expansion vessel, or poor seals on connections.

Prevention: Regular pressure checks on the gauge. If pressure repeatedly drops, the leak needs to be found and fixed. The problem is in the system, not in the heat pump.

Incorrectly configured controls

Flow temperature set too high, incorrect weather-compensation curves, or unsuitable backup source settings — all of these increase energy consumption and shorten component lifespan. The heat pump then operates in a mode it wasn’t designed for and wears out unnecessarily.

Prevention: Have the settings configured or checked by a qualified technician. The investment in correct settings pays for itself in operating costs within a single heating season.

Poor placement of the outdoor unit

Insufficient clearance around the outdoor unit or blocked airflow causes excessive frost build-up and reduces efficiency. The defrost cycle handles the problem, but if frosting is chronic, it’s worth reviewing the placement.

Prevention: Follow the minimum clearances specified in the installation manual. Ensure free airflow around the entire unit.

Actual faults are rare

Compressor, fan, or control electronics failure can of course happen, but these are exceptions. Our service statistics show that a genuine technical fault in the heat pump occurs in fewer than 10% of all service calls, typically after many years of operation or as a result of prolonged unsuitable operating conditions. We source all critical components from proven suppliers and every heat pump undergoes final inspection before dispatch.

How to prevent problems

The best repair is one that never has to happen.

Quality installation is the foundation of everything. The majority of operating problems are rooted in how the entire heating system was designed and built. Installation should be carried out by a proven company following the installation manual — not by “a handy neighbour with a welder.” A poor installation will cost you more than the price difference.

Regular servicing once every two heating seasons catches minor problems before they escalate. A service visit costs 2,000—5,000 CZK — a fraction of what an unexpected repair costs.

Remote monitoring via webserver lets you track temperatures, pressures, and error codes from anywhere. Many problems can be detected and resolved before the customer even notices them. On our heat pumps, the webserver is included as standard.

Correct flow temperature settings matched to the heating system type. Underfloor heating doesn’t need 55 °C, and the heat pump will thank you with lower consumption and a longer lifespan.

Concerned about your system?

If you feel your heat pump isn’t performing as it should, it may not mean a fault. It could be a settings issue, a maintenance need, or simply different behaviour from what you’re used to with a gas boiler.

Get in touch — whether you’re already our customer or considering a heat pump. We’ll help you figure out what’s going on and suggest a solution. And if it turns out to be just “cold radiators” in a warm house, we’ll reassure you that everything is working perfectly.