A Hotjet heat pump does not have to be the only heat source in a building. As the primary source, it covers 70–90% of annual heating demand. For the remaining peaks – such as extreme frost or a need for high output temperature – a secondary source steps in. This can be a pellet boiler, gas boiler, or electric heating elements. The Hotjet controller manages the entire system automatically.

What is a hybrid system and how does it differ from bivalence

Bivalence means the system can use a supplementary heat source. Switching occurs based on a simple temperature threshold, time schedule, or heat deficit. The goal is to deliver heat – regardless of the cost.

The Hotjet hybrid system goes further. The controller continuously evaluates the operation of all sources based on the current coefficient of performance (COP) and energy prices. The heat pump is always the primary source. The boiler is secondary and only activates when it is economically or technically more advantageous. It is not simple switching but a continuous calculation: “Electricity is expensive right now and it’s cold outside, so the heat pump has low efficiency – heating with the boiler will be cheaper.”

Why the heat pump is always the primary source

A heat pump operates with a COP of 3–5 for most of the heating season. For every kWh of electricity consumed, it delivers 3–5 kWh of heat. No boiler can match this – neither gas condensing nor pellet. That is why the heat pump is always the primary source and the boiler merely a supplement.

The boiler takes over when the COP drops so low that operating the heat pump costs more than direct combustion. This typically occurs at temperatures below −10°C or when output temperatures above 60°C are required.

How the Hotjet controller decides

The RVS controller in Hotjet heat pumps does not switch between sources based on a simple temperature threshold. It continuously compares the cost per kWh of heat from the heat pump and the secondary source – in real time.

Input data for decision-making

For the controller to correctly evaluate which source should run, it needs to know:

- COP characteristics – how the coefficient of performance changes depending on outdoor temperature and output water temperature. The controller knows this curve from the parameters of the specific heat pump model.

- Energy prices – the user enters three tariffs: high-rate electricity for the heat pump, low-rate electricity for the heat pump (Smart Grid, dual-tariff), and the price of alternative fuel (gas, pellets).

Economic switching logic

The controller calculates in real time the point at which heat pump operation becomes more expensive than boiler operation:

- Cost of heat from the heat pump = electricity price ÷ current COP

- Cost of heat from the boiler = fuel price ÷ boiler efficiency

When the outdoor temperature drops so much that the COP falls below the critical threshold, the controller shuts down the heat pump and starts the cheaper secondary source.

An important detail: the controller accounts for the current tariff. During the low electricity tariff, it tolerates a lower COP than it would during the high tariff. The reduction in the COP criterion corresponds to the ratio of the two tariff prices. In practice, this means the heat pump runs longer during the low tariff – even at lower outdoor temperatures.

Control strategies

- By COP – the boiler takes over when the COP drops below a set value. A straightforward and reliable strategy.

- By energy price – comparison of cost per kWh of heat from both sources. A purely economic decision.

- Combined strategy – considering both COP and price simultaneously.

- Forced operation – in certain situations, the controller forces a specific source. During PV surplus, the heat pump always runs because electricity is essentially free. During boiler maintenance, the boiler is locked out and the heat pump runs alone. And during a heat pump failure, the boiler takes over as backup without interrupting heating.

Secondary source configuration

The Hotjet controller supports three ways of connecting an external boiler:

- Classic bivalence – boiler controlled via a relay on the thermostat input. Simple wiring, works with any boiler.

- Hybrid with communication – full integration via bus. Bidirectional communication, single control panel, boiler output modulation.

- Hybrid with relay and logic – heat pump and boiler as a single unit with advanced switching logic.

In addition to boilers, the controller also supports electric heating elements at multiple points in the system. In the DHW tank, they provide rapid reheating and anti-legionella function. In the buffer tank, they supplement when heat pump output is insufficient. And a flow-through electric heater at the heat pump output provides instant reheating or freeze protection.

Setting lockouts and target temperatures

The controller allows defining conditions for each source separately. The heat pump is locked out below −15°C or when output above 65°C is required. The boiler is locked out above +15°C, when its operation would be unnecessary, or during PV surplus. Electric heating elements can be locked out during peak demand, for example between 5 and 8 PM.

Different sources can also have different target temperatures. The heat pump heats DHW to 50°C, where it has optimal COP. The boiler reheats to 60°C for greater comfort. And the heating element during PV surplus heats water up to 70°C to accumulate as much energy as possible.

Heat pump + pellet boiler

Combining a Hotjet heat pump with a pellet boiler is one of the cleanest hybrid configurations – both sources work with renewable energy. The heat pump is the primary source year-round. The pellet boiler takes over in winter when the COP drops below 2 and burning pellets becomes cheaper.

How it works

The heat pump covers heating from autumn to spring. During transitional periods and mild frosts, when the COP is highest, it runs alone. When the COP drops below 2 in winter, it switches to the pellet boiler. In spring and autumn, it pays to turn off pellets entirely. The controller switches automatically and can smoothly start and stop both sources across their full output range.

Operating costs of the hybrid system are 30–40% lower than either a standalone heat pump or a standalone pellet boiler. Each source works only where it performs best.

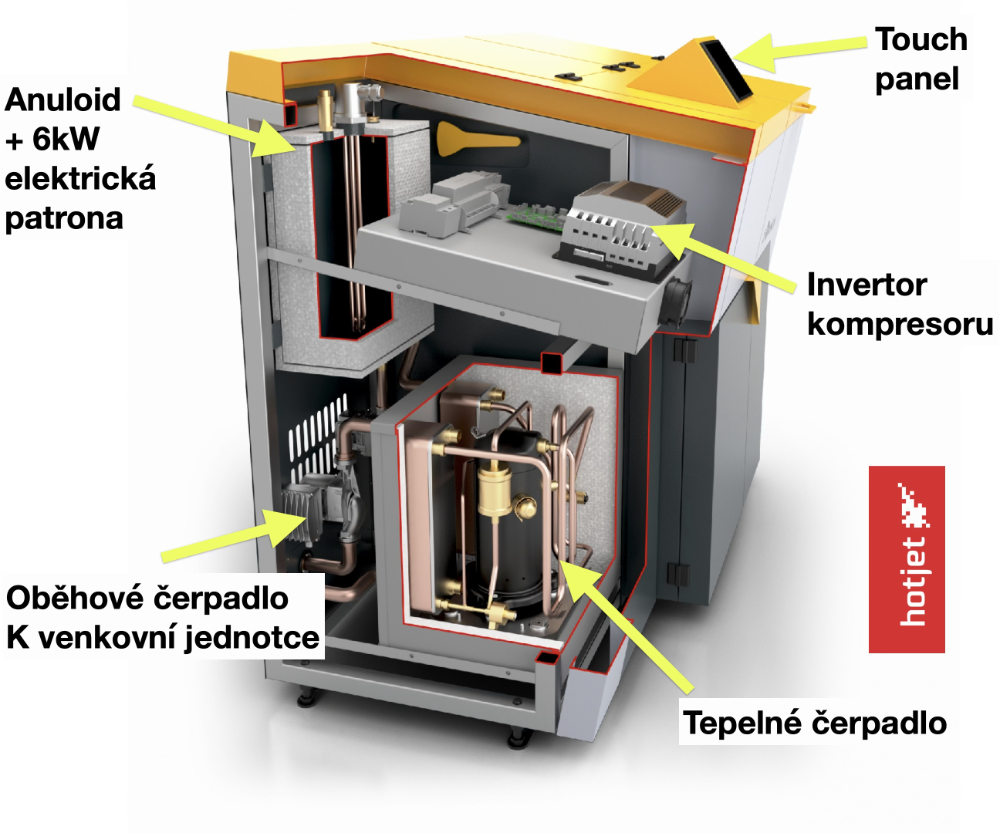

Hotjet H25/10

Hotjet offers the H25/10 hybrid heat pump, which combines a pellet boiler with a rotary burner rated at 25 kW and an air-to-water heat pump at 10 kW in a single unit. In normal operation, the system works in the 0–25 kW range. The Siemens control system continuously evaluates the current cost of produced heat and determines which source should run.

The investment cost of the hybrid boiler is comparable to a 20 kW heat pump that would be needed for year-round coverage. However, operating costs are significantly lower because both sources complement each other.

Modular acquisition

The customer does not need to invest in the complete hybrid system all at once. They can first purchase the pellet boiler and add the Hotjet heat pump at any time later. The lifespan of the entire system – especially the heat pump – is significantly longer in hybrid mode than with year-round operation of a single source. The heat pump is simply not stressed under extreme conditions.

Blackout protection

The hybrid pellet boiler has one crucial advantage over other solutions: it works even during a power outage. With a tonne of wood pellets in reserve, it can heat a house for several weeks. Owners of gas boilers or standalone heat pumps will be without heat during a blackout – even if they have photovoltaics. A hybrid pellet boiler combined with PV and battery storage provides this protection.

Why heat pump + pellets

- 100% renewable sources – pellets and heat pumps meet renewable energy requirements, no dependence on fossil fuels.

- Lower operating costs – 30–40% compared to a standalone option. Each source works only where it performs best.

- Longer heat pump lifespan – reduced stress in hybrid mode extends compressor life.

- Subsidy advantages – combining two renewable sources may qualify for a more favourable subsidy category.

- No heating system reconstruction – existing radiators and piping can be kept.

- Blackout protection – the pellet boiler provides heat even without electricity.

Who is it for

- Larger or older family houses with a heat loss of 15–25 kW.

- Properties without a gas connection.

- Renovations where the existing boiler room can accommodate a pellet boiler with storage.

- Homeowners who want to minimise dependence on fossil fuels and electricity.

Heat pump + gas boiler

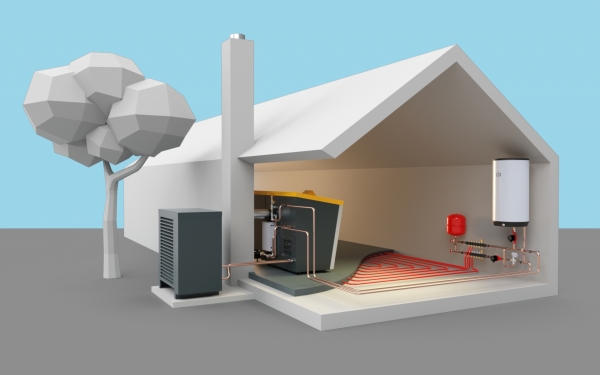

A gas condensing boiler is the most common secondary source in Hotjet hybrid systems. The reason is simple – most homes already have a gas boiler. Just add a Hotjet monoblock heat pump as the primary source and the existing boiler automatically becomes a backup for extreme frost peaks.

How it works

The Hotjet heat pump covers 80–90% of annual heating demand. The gas boiler steps in only during peak frost when the COP drops below the economic threshold, or when temperatures above 60°C are required for older radiators. The controller switches automatically – the user does not need to do anything.

Gas boiler compatibility

Standard Hotjet monoblock heat pumps can be combined with gas boilers in two ways:

- Boilers with compatible Siemens controls (Baxi, Brötje, Geminox and others – compatibility must be verified for the specific model) – full bus integration, bidirectional communication, single control panel.

- Standard gas boilers – control via relay on the boiler thermostat input. Works with any boiler, the Hotjet controller manages switching based on COP and energy price economics.

The easiest path during renovation

The heat pump + gas hybrid system is the easiest path to efficient heating in terms of construction work. The existing boiler stays and serves as a secondary source and backup. Piping stays – radiators and underfloor heating can be kept. The heat pump only needs to be sized for 60–70% of the heat loss, so it is smaller and cheaper. No building modifications are needed – just the outdoor heat pump unit plus connection to the boiler room.

Why heat pump + gas

- Immediate savings – gas consumption drops by 50–70% from day one.

- Low investment – smaller heat pump + existing boiler saves 30–40% compared to a standalone heat pump.

- Reliability – two independent sources, no heating interruption.

- Gradual transition – when the gas boiler reaches end of life, the heat pump can operate standalone with electric heating elements.

Who is it for

- Family houses with an existing gas boiler.

- Renovations with minimal building work.

- Properties with radiator systems where the boiler covers temperature peaks.

- Apartment buildings with a central gas boiler room.

Combining with photovoltaics

Adding photovoltaics further improves the economics of the hybrid system. PV surplus powers the heat pump at virtually zero electricity cost. The Hotjet controller supports Smart Grid Ready and automatically switches charging priorities.

In summer, the heat pump heats DHW and the pool from solar energy. During transitional periods, PV covers heat pump operation. In winter peaks, the boiler supplements. The triple combination of PV + heat pump + boiler is among the most cost-effective heating methods today.

Want a hybrid solution?

Contact us – we will design the right combination of a Hotjet heat pump with a secondary source for your home.